It would be all but impossible (and certainly inefficient) to build bridges, high-rises, roads, or any other large project without construction cranes. They are used to raise or lower heavy objects, transport objects around the construction site, and are essential for the building or deconstructing large structures.

Many different types of cranes have been developed to meet specific needs of given projects, because they are vital to building so many different structures.

A crane’s machinery will be different depending on the kind of lift it’s designed to execute. This guide will introduce a few of the many kinds of construction cranes available and a bit about which type of project they are most helpful for.

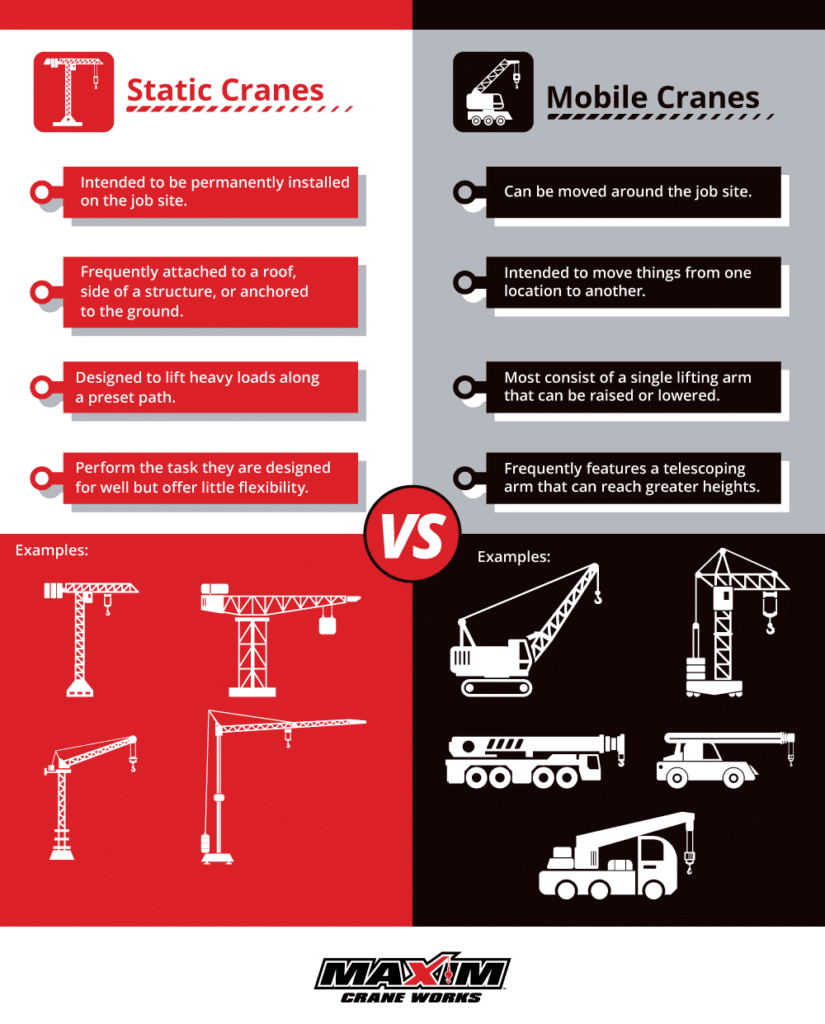

Static Cranes and Mobile Cranes

The many types of cranes in construction can be broken down into two basic categories: static and mobile.

Static cranes:

These cranes are to be used in a single space and move things along a predetermined path.

They are frequently attached to the roof or side of a structure.

They can also be anchored directly to the ground.

In any case, these are designed to stay in a single spot for the duration of construction.

Mobile cranes:

- As the name implies, these cranes are designed to move about the jobsite during a construction project.

- These are intended to be used to move things from one place to another quickly and easily.

What Are Static Cranes?

Static cranes are used mostly for long-term construction projects or are intended to be permanently installed on a jobsite.

Static Cranes:

- Are designed to lift and move heavy loads along a preset path

- Are designed to accomplish pre-planned tasks

- Perform the task they are designed for very well but offer little flexibility on the job.

There are several types of static construction cranes, each designed to meet different needs.

Tower Cranes

Tower cranes are perhaps the most widely recognized type of crane for construction, if for no other reason than they are hard to miss. Often quite large, their crane towers stand tall in the middle of construction sites for all the world to see.

Tower cranes are made up of the tower, or mast, and the jib, the arm that extends out from the mast. The jib can move a full 360° around the mast, with a trolley that runs up and down the full length of the jib, allowing the block hook to be lowered to the correct location.

Static cranes are the type most often used to build large structures over a longer timeline. They’re commonly used in urban areas where space is limited and the public is rarely far away. Their stability provides an extra layer of safety for both those who work at the sight and those outside the fencing.

They are powerful and capable of lifting large weights very high if necessary, but they are limited to a single area. While they do extend and rotate, there is still a limit to their range of motion.

There are three primary types of tower cranes, including:

- Hammerhead cranes

- Luffing tower cranes

- Self-erecting tower cranes

Hammerhead Cranes

Hammerhead cranes resemble an upside-down L, with the jib remaining at a set level. The jib can usually rotate but cannot be raised or lowered. This model is frequently found on loading docks where many cranes may be operating simultaneously at various levels. They are also used in situations where space may be limited, like inside a structure or at particularly tight construction sites.

There are two basic designs for tower cranes: the A-frame, and the flat top.

The A-Frame:

- Uses a metal structure to connect cables from the jib to the counter jib, a short but has a heavily weighted structure behind the jib

- This is used for leverage and allows this type of tower crane to lift heavier weights

The Flat-Top:

- Has no additional structures above the tower and is used for lifting lighter weights

- Features a simplified design with no overhead bracing, making it easier to transport and assemble, ideal for projects with height restrictions or where multiple cranes are operating in close proximity

Luffing Jib Crane

The luffing jib type of tower crane is very similar in structure to the hammerhead but has one major difference. The jib can be raised and lowered on luffing jib construction cranes. This design gives them added flexibility while allowing them to lift heavier weights.

The luffing crane is more expensive than the hammerhead, but can be more efficient with a smaller rotation radius, allowing it to be used in tighter construction sites. It can also be used where multiple cranes are operating at the same time.

Self-Erecting Cranes

Relatively speaking, the self-erecting cranes are the lightweights of the static crane family. They are designed to be easily set up and dismantled.

Self-erecting cranes are ideal for working in tight spaces or for shorter-term construction jobs. Their major shortcoming, however, is that they cannot lift as much weight as the other types of tower cranes.

Level Luffing Cranes

Similar in appearance and function to the tower luffing cranes, the level luffing cranes have one major difference — they do not have trolleys that run along the jib. Instead, the hook block is fixed at the end of the jib, and the jib itself moves up and down to move the load. This design allows the load to stay level while being lifted.

This type of construction crane is most often used for shipbuilding and loading and unloading freight.

What Are Mobile Cranes?

Mobile cranes can be moved around a construction site or even from site to site as needed. They are usually mounted on trucks but can also be found on railcars and boats, and are usually outfitted with outriggers to prevent them from tipping over while the crane is lifting.

Mobile cranes:

- Are meant for temporary use in any given area

- Most consist of a single lifting arm that can be raised or lowered

- Frequently feature a telescoping arm to allow the crane to reach higher places

There are several different kinds of mobile cranes, including:

Crawler Crane

The crawler crane is mounted on a large heavy vehicle with treads, similar to those a tank uses. These treads give them the ability to move over soft, rough, or marshy ground, which heavy trucks with wheels would likely get stuck in. They are frequently used at the beginning of construction projects when the ground is freshly torn up.

Their large size gives them a powerful system of hydraulics and a heavy lifting arm. They can lift the heaviest weights of all the mobile construction cranes.

Rough-Terrain Cranes

Similar in function to the crawler, the rough-terrain cranes are designed to traverse difficult ground conditions. However, they are smaller and lighter, which allows them to be used in tighter spaces than the crawlers. These cranes are not as powerful or stable, so they cannot handle lifting as much weight.

All-Terrain Cranes

All-terrain cranes are similar to the rough terrain crane except that they can be driven on the road. This means that they can easily move from one construction site to another in addition to being able to traverse most ground types.

The cranes are mounted on trucks with anywhere from 6 to 18 wheels and can lift substantially larger weights than rough-terrain cranes. To accomplish this, some assembly may be required at the worksite — including installing the outriggers and boom weights.

Truck Cranes

These cranes offer great flexibility at a relatively low cost. These vehicles don’t need to be hauled to and from job sites and are safe for traveling on public roads. This makes them ideal for construction companies that may not require heavy lifting and have multiple projects at the same time.

These cranes may also be called a boom truck, a truck crane, or a truck mounted crane (TMC). They can also be used to easily move objects from one place to another within the construction site, as long as the ground is not freshly dug or marshy. They can be used to lift as much as 110 tons if the outriggers are properly employed.

Carry Deck Cranes

These are the smallest of the types of cranes for construction. They are simple in design, with a crane mounted on a four-wheel deck.

Carry deck cranes are primarily used to move objects from one area to another within a construction site. They can only handle weights of up to 25 tons, which they load onto their deck and haul away.

The Right Crane for the Job

As you can see, there are a great many options to choose from when considering a crane for your construction projects. Knowing exactly what your needs will be before you begin your hunt for the right crane can help you save yourself a lot of stress and money down the line.

If you have a long-term project or one that requires a lot of upward building, such as a high-rise, then a static crane may be the right choice. If you’re doing construction on newly broken ground, a mobile crane may be a better choice, especially one that can handle rough terrains like the crawler or all-terrain.

When your project is on the smaller side or if you will need the cranes at multiple sites, you should choose one that can travel the roads. While they’re designed for lighter loads, they make up for this in their flexibility and ease of transport.

Remember, we’re here to support you as your perfect partner. We have one of the largest, most modern fleets of cranes and other lifting equipment available, and our staff is always ready and happy to help you. We will make sure you get the right equipment for the job — regardless of how large or small the lift might be. Contact Maxim Crane Works today to consult with one of our professionals today.