From tower cranes to carry deck cranes, there’s no shortage of heavy lifting machines available to engineers today to take their projects to new heights. Each one comes with its own advantages and shortcomings, though, and choosing the wrong one can waste valuable time and resources on a project that can afford to lose neither. Because of that, selecting the right tool for the job is a must.

Due to their versatility and ruggedness, the crawler crane is one of the most popular cranes available. Differing from other cranes in that their undercarriage is mounted to a set of tracks on each side called crawlers, crawler cranes have what it takes to traverse the challenging terrains common to many construction sites — and as you’ll see later on, this gives them multiple other advantages that come with the turf.

What Is a Crawler Crane?

Cranes are versatile machines used for heavy lifting, and they come in various types to fit different needs. Some cranes are stationary, some tower-like structures are built alongside buildings, and others can even float on barges. In addition to crawler cranes, popular types of cranes include:

- Tower cranes

- Carry Deck cranes

- All-terrain cranes

- Rough terrain cranes

- Stacker cranes

- Bulk-handling cranes

- Bridge cranes

What sets crawler cranes apart is their unique method of movement. Unlike other mobile cranes, crawler cranes move using tracked crawlers similar to those found on construction machines like backhoes or bulldozers. This design offers several key advantages:

- Rugged Terrain Operation: The tracked crawlers provide excellent stability and mobility on rough and uneven surfaces, making them ideal for challenging job sites.

- Enhanced Stability: The broad base of the crawlers distributes weight more evenly, increasing overall stability.

Many crawler cranes feature a lattice boom, a structure that distinguishes them further. Compared to telescopic booms, lattice booms have several advantages:

- Lightweight and Long: Lattice booms are typically lighter and longer, allowing for greater reach without compromising stability.

- Higher Load Capacity: The design allows these cranes to handle heavier loads, making them suitable for projects requiring significant lifting power.

These features make crawler cranes highly effective for various construction tasks, especially those involving heavy loads and challenging terrains. For specific technical specifications, it’s crucial to consult the manufacturer’s load charts to help ensure the right crane is selected for the job.

How Have Crawler Cranes Changed Over the Years?

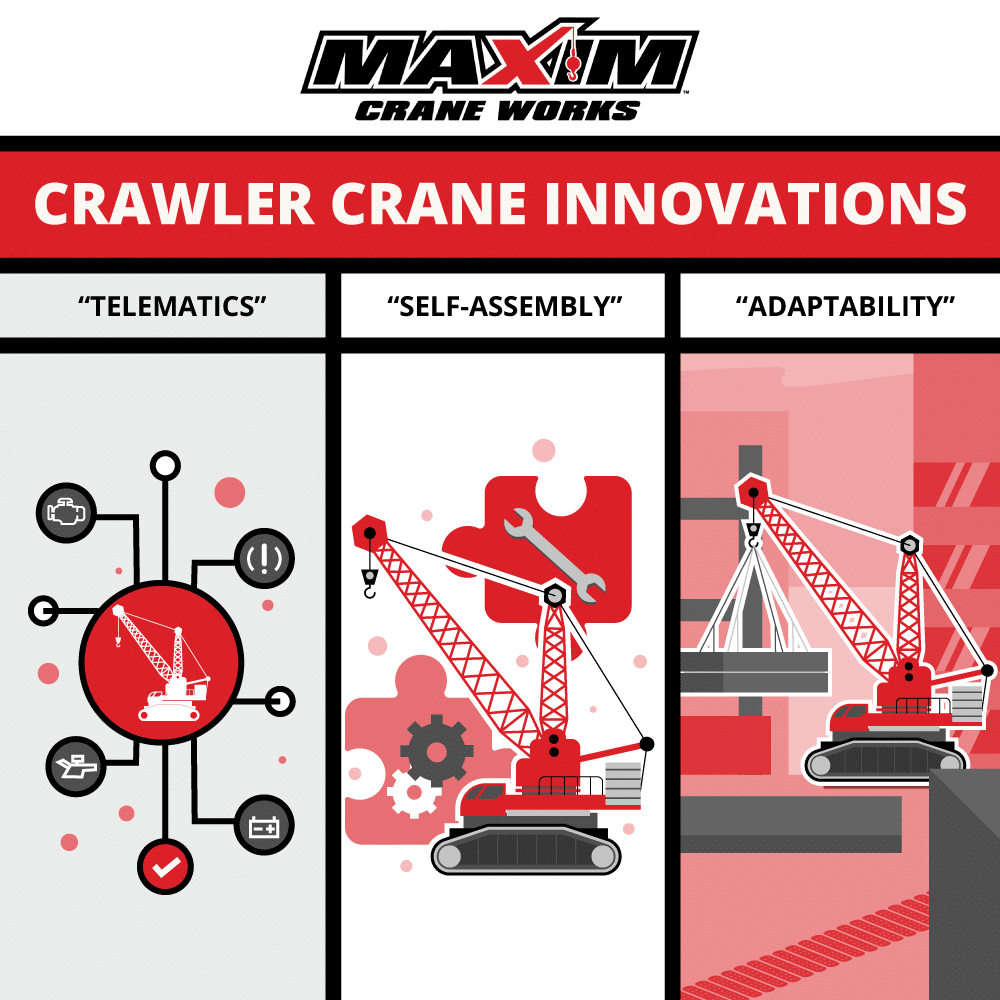

Cranes have been around for thousands of years, so it’s not surprising that they’ve undergone significant transformations. Crawler cranes, once considered bulky machines, have evolved into versatile construction powerhouses meeting a wide range of project needs. Some of the most notable innovations include:

- Telematics: Modern crawler cranes are equipped with advanced telematics systems that provide real-time updates on machine condition and maintenance needs. These report-generating systems help prolong the lifespan of the crane, reduce downtime, and improve overall system operability by enabling proactive maintenance.

- Self-Assembly: One of the most groundbreaking advancements is the incorporation of self-assembly mechanisms. This innovation, often found on telescopic crawler cranes, minimizes startup time and reduces worker effort, allowing construction sites to set up their crawler cranes more quickly and efficiently. The self-assembly feature significantly decreases the time and labor traditionally required for assembly.

- Adaptability: Engineers have made remarkable strides in reducing the cumbersome size of crawler cranes. Modern designs allow these cranes to be reconfigured to fit into more narrow and confined spaces, enhancing their utility across diverse construction environments. This adaptability makes crawler cranes more versatile and easier to deploy in challenging settings.

Additionally, crawler cranes now feature more sensitive controls for precision handling and environmentally friendly engines to meet current sustainability standards. These advancements not only improve operational efficiency but also align with modern environmental regulations.

With these cutting-edge developments, crawler cranes have become increasingly indispensable for a variety of construction, industrial, and maintenance projects. Their continued evolution ensures they will remain a critical tool for meeting the ever-growing demands of the construction industry.

Crawler Crane Load Capacity

Crawler cranes are renowned for their exceptional lifting capabilities, which make them indispensable for demanding projects. Their design allows them to handle substantial weights with ease. Key elements contributing to their load capacity include:

- Lattice Boom Efficiency: The lattice boom design offers a high strength-to-weight ratio, enabling the crane to lift heavier loads without compromising stability.

- Robust Construction: Crawler cranes are built for durability and strength, allowing them to perform in challenging environments while maintaining high load capacities.

- Load Distribution: The tracked crawlers distribute weight more evenly, providing a solid foundation for lifting and reducing ground pressure.

Crawler cranes equipped with a telescopic boom offer versatility but typically lower load capacities compared to their lattice boom counterparts. For precise lifting capacities, manufacturer load charts are essential resources, detailing the specific capabilities of each crane model.

What Applications Are Crawler Cranes Used For?

Crawler cranes excel in a variety of challenging environments, making them highly versatile for numerous construction applications. The unique features of crawler cranes make them particularly well-suited for:

- Sites With Difficult Driving Conditions: Crawler cranes are designed to navigate tough terrain effortlessly. The tracked crawlers offer superior mobility on soft or uneven ground where other types of cranes might struggle or become stuck.

- Heavy Lifting at High Heights: The frequent use of lattice booms in crawler cranes allows for lighter arms and greater reach. This makes them ideal for projects requiring the lifting of heavy loads to considerable heights, without sacrificing stability.

- Greater Operating Radius: The reduced boom weight achieved through lattice booms provide for a greater operating radius compared to cranes with telescopic booms. This feature is crucial for tasks that demand both reach and mobility.

- High Stability Needs: The wider contact area provided by the tracked crawlers distributes weight more evenly, enhancing stability. This often eliminates the need for additional support systems like outriggers, making crawler cranes especially suitable for tasks requiring a significant degree of stability.

- Construction Sites With Soft Ground: When working on soft ground conditions, crawler cranes can generally maintain their stability and mobility. However, for extremely soft or unstable ground, using crane mats or additional stabilization techniques might be necessary to help ensure smooth operation.

These attributes make crawler cranes the go-to solution for a variety of construction, industrial, and maintenance projects, particularly those involving challenging terrains and significant lifting requirements.

Best Types of Projects for Crawler Cranes

Crawler cranes are particularly well-suited for a wide range of heavy-duty projects, thanks to their robust design and exceptional capabilities. Here are some of the best types of projects where crawler cranes excel:

Large-Scale Construction Projects

Large-scale construction projects often require the unique features of crawler cranes. For instance, these cranes are indispensable in skyscraper construction, handling the heavy lifting and high reach needed for tall buildings. Similarly, in bridge building, the crane’s stability and lifting capacity are essential for assembling large sections, including support beams and trusses.

Industrial Installations

In the realm of industrial installations, crawler cranes prove invaluable. They are frequently utilized in power plants to manage heavy components such as turbines and generators. Chemical plants and refineries also benefit from crawler cranes, as these projects often involve lifting heavy equipment into precise positions where stability and precision are paramount.

Infrastructure Development

Infrastructure development is another area where crawler cranes excel. Railway projects require the ability to move heavy materials and equipment over uneven terrain, a task perfectly suited for crawler cranes. Furthermore, highway and overpass construction benefit from the cranes’ capability to lift large concrete sections and place beams accurately.

Marine and Port Work

Marine and port work also see frequent use of crawler cranes. The ability to maneuver through rugged terrains makes them ideal for constructing docks and piers. In shipbuilding and repair, their precision and heavy lifting capability are essential for the construction and maintenance of ships.

Renewable Energy Projects

Renewable energy projects are on the rise, and crawler cranes play a significant role in their success. Wind farm assembly involves installing wind turbines efficiently and safely, a task made easier with the crane’s considerable reach and lifting capacity. Solar farm construction also leverages crawler cranes to place heavy solar panels and supporting structures, especially in areas with difficult terrain.

Heavy Equipment Installation

Heavy equipment installation in mining operations and factory assembly demonstrates the versatility of crawler cranes. In mining, these cranes handle the heavy lifting required for installing large mining equipment. Factory assembly involves installing heavy machinery where both reach and stability are necessary, showcasing the crane’s multifaceted utility in various industrial applications.

These types of projects benefit significantly from the unique capabilities of crawler cranes, making them an indispensable part of large-scale, demanding operations where reliable heavy lifting is crucial.

Successful Crawler Crane Deployment at Denali Logistics Park Project

Maxim Crane Works played a pivotal role in the speedy construction of Denali Logistics Park, a major 216-acre logistics and storage site near Denver International Airport. Arch-Con and Suntec Concrete selected Maxim due to their extensive experience in tilt-up construction.

For this project, Maxim’s crawler crane lifted over 60 panels for each of the three buildings, with each panel weighing 172,000 lbs. The equipment used included a Manitowoc 2250 Series 3 lattice-boom crawler crane with a 300-USt capacity, rigged with substantial counterweight and a tilt-up spreader bar.

Maxim’s experience helped to ensure that more than 100 concrete panels were successfully lifted and placed without any safety issues or project delays. The project was completed on time and within budget, demonstrating the effectiveness and reliability of crawler cranes in large-scale construction projects.

The Importance of Crawler Cranes on Your Job Site

The rugged versatility of crawler cranes makes them indispensable for ambitious construction projects. Their tracks provide superior weight distribution, offering unmatched stability and maneuverability on rough or uneven terrain. Most crawler cranes utilize a lattice boom, granting them extended reach and enhanced lifting capacity, essential for tackling heavy loads and reaching significant heights. Some projects simply couldn’t be executed without the strength and stability provided by crawler cranes.

When your project requires the reliable lifting power of a crawler crane, Maxim Crane Works stands ready to assist. As a coast-to-coast crane rental company, Maxim Crane specializes in delivering innovative solutions for a wide range of lifting requirements. With one of the most diverse and extensive fleets of portable cranes in the world, and over 50 locations across the United States, we offer unparalleled management services, including transportation, insurance programs, and more.

Our expertise helps to ensure we can match you with the perfect crane to meet your project’s unique demands. Get in touch with us today to find out how our crawler cranes can help get your construction project off the ground successfully.