Tilt-up construction is a method of building that uses large concrete panels that are cast on-site and then tilted into place. This construction technique has many advantages and is often used in several types of building construction, including warehouses, manufacturing facilities, offices, schools and more.

It’s construction cranes that help make tilt-ups possible, and Maxim has experience in a variety of tilt-up jobs. Read on to learn more about this type of construction.

The History of Tilt-Up Construction

Tilt-up construction was invented in the 1900s to make building more efficient. In fact, a Methodist church in Zion, Illinois was built using this method in 1918 and stands to this day.

Fast forward to the years following World War II – a boom in construction combined with a shortage of labor and the availability of high-capacity construction cranes helped tilt-up construction gain momentum into the 1940s and 50s. Today, advances in equipment and concrete formulation have optimized tilt-up construction and helped make it a more common building method, moving beyond “big box” buildings to more sophisticated structures.

Employing tilt-up construction allows buildings to have the durability of reinforced concrete while being completed in a quicker, more efficient way.

How a Tilt-Up is Completed

Developing a detailed lift plan is essential before planning a tilt-up project. Maxim’s Engineering department often helps contractors make plans to successfully execute tilt-ups.

“Quite a lot goes into tilt-up projects, but for many buildings, the benefits are outstanding for the contractor and end users,” said Dan Durrett, PE, Director of Engineering at Maxim Crane Works.

A tilt-up project generally starts with pouring the floor slab for the structure. This floor slab also serves as the casting surface for the walls as they are completed.

Then, crews build a form out of lumber that is a mold of each wall panel. Once that is complete, crews add reinforcing steel bars (rebar) that will help strengthen the concrete when it is poured. Often, insulation is added between the layers of concrete to provide insulation across the entire area of the wall.

Workers also add pieces that will provide points to assist in lifting the panel in place once it’s completed. Workers also will spray a bond-breaking solution to keep the concrete wall panel from sticking to the floor. Once concrete is poured, it will cure within 7-10 days.

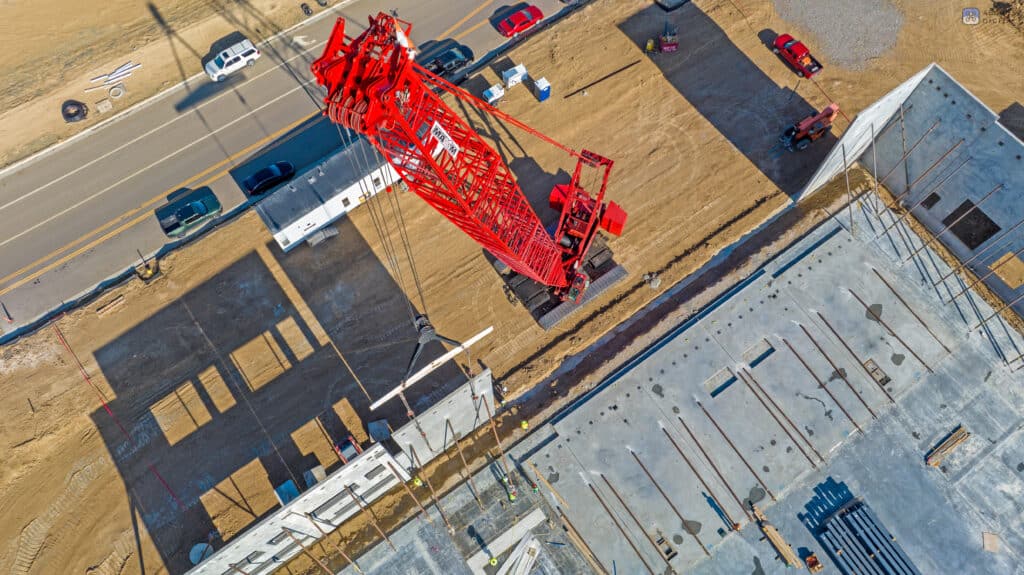

After the concrete is set, a crane moves into position to lift the panels into place along a vertical line to form the building wall. This offers a dramatic visual as the building quickly takes shape, one panel at a time. Depending on the size of the panel, reinforcing braces are put in place to hold the panel in position temporarily until it can be tied to other panels using metal braces and concrete. Progress can be fast – An experienced crew can set as many as 40 panels a day!

The last step of a tilt-up project involves removing the bracing and sealing the joints between the panels. Exterior finishes can be added at this stage. Once the completed structure is inspected, a roof structure will be added, and mechanical/electrical/plumbing contractors can complete their part of the project.

Maxim Cranes and Tilt-Ups

With a fleet of cranes capable of handling the demands of a tilt-up project, contractors have often turned to Maxim. Recently, Maxim was asked to lift massive 90’ tall, 400,000-lb panels as part of a distillery plant in Kentucky. This was a world record-breaking lift of insulated panels for contractors Clayco and Concrete Solutions.

Maxim also assisted in completing the Denali Logistics facility – a 760,000 square foot building that is part of a 216-acre logistics and storage site near Denver, Colorado. Contractors Arch-Con and Suntec turned to Maxim to lift a series of 172,000-pound panels into position to complete the building.

If your infrastructure project needs reliable and efficient heavy lifting solutions, consider Maxim Crane.

As a leading provider of crane rentals, heavy hauling, specialized rigging, and other rental services, Maxim offers a comprehensive suite of services tailored to meet your unique requirements, including tilt-up projects.

Our commitment to safety, quality, and performance guarantees you peace of mind during your construction projects.

For a detailed understanding of how our services can facilitate your project, please reach out to us today. Our team of experts is ready to guide you through our versatile equipment options and help you choose the most suitable solutions for your lifting needs.