The indisputable lifting champion when it comes to construction cranes is the almighty tower crane. Without it, some of the most iconic city skylines would look entirely different. Thinking about these construction site staples, most people can’t help but wonder how they can function.

Tower cranes’ tall and slender figure makes it hard to believe they can carry so much weight. If you’re curious about these marvels of the construction world, we’ve got you covered. Read on to answer all your tower crane-related questions once and for all.

The Evolution of the Tower Crane

Derrick tower cranes were the first tower cranes ever to see the light. Named after a type of gallows developed by Thomas Derrick, these lifting tools featured a boom attached to a rotating base with a hinge. Back then, there was no way to rent tower crane equipment. Construction crews had to come up with this type of ingenious lifting mechanism.

The early 20th century brought in a new design. Construction workers got tired of trying to maneuver large heavy equipment in denser urban areas. This led to the creation of the Gantry tower crane. Its tower featured suspended beams and trolleys. This model wasn’t that efficient, however, as the extra elements made it too heavy for most urban uses.

The tower crane we know and love appeared in 1949. The German Hans Liebherr conceived the machine to support post-war efforts to rebuild major cities. Liebherr’s design featured a rotating tower and horizontal working arm. It had a 360-degree range that made construction work much easier. Little did Liebherr know that his design would become a major inspiration for future prototypes.

In the 1970s, most manufacturers stopped making hydraulically powered tower cranes, switching to electric alternatives instead. Modern models have dozens of features that the crane operators of old could only dream of. Today, tower cranes are more powerful, versatile, and energy-efficient than ever.

Importance of Tower Cranes at the Construction Site

Today’s tower cranes allow development companies to work faster and more efficiently. These heavy-lifting staples are essential for tackling the most arduous tasks effortlessly. Imagine a large construction site without a single tower crane on the premises. Not even all the manpower on a job site could lift an electricity generator up several flights of stairs.

The construction industry would be eons behind if it weren’t for tower cranes. Not only would we be missing the majestic skyscrapers of modern cities, but we’d also be missing their bridges, elevated railways, and more. Construction sites would be a lot less energy-efficient.

How Do Tower Cranes Work and What Exactly Are They Used for?

A tower crane is a construction site staple across the globe. Their seemingly never-ending towers rise hundreds of feet above the ground to dot just about every major city’s skyline. These gigantic tools are a lifesaver when a project requires heavy lifting at extreme heights, but purchasing a tower crane can be pretty pricey. That’s why it’s common for contractors to look for tower cranes for rent.

Aside from providing the ultimate urban aesthetic, tower cranes come in handy for lifting steel, concrete, and other heavy materials. They also offer an easier alternative to carrying bulky equipment around.

Parts of a Tower Crane

The way a tower crane functions has a lot to do with its components. To better understand a tower crane’s abilities, let’s have a look at its essential elements.

Base Support

The base support is located at the bottom of the tower and often attached to a concrete pad on the ground. Alternatively, the base support may be attached to a steel grillage or ballasted chassis set on the ground or on top of an existing structure.

Tower

Also known as the mast, the tower is the vertical element that gives the crane its notable height. This component extends from the ground up, and it supports other elements like the cab, the hook, and the counterweights. Towers often feature steel latticework for extra strength.

Turntable

The turntable is the part of the crane that allows the arm to rotate. This component uses the same technology we often see in windmills. Thanks to it, the jib has a broader range of motion.

Operator’s Cab

The cab is the box where the operator sits while working with the tower crane. It contains the computer and joysticks as well as the control systems.

Jib or Working Arm

Also known as the crane’s working arm, the jib is the horizontal component sticking out from the top of the tower. This element’s purpose is to support and position the load being lifted.

Trolley and Hook Block

The trolley is the piece that moves back and forth across the jib. The hook block serves as a pulley system that allows the hook to travel up and down the tower.

Counter Jib

The counter jib extends in the opposite direction of the jib and helps the tower crane maintain its balance.

Counterweight

Counterweights balance the load of the lift. Without them, the load capacity would have to be significantly lower to maintain stability. You’ll find this essential element at the rear of the counter jib, opposite of the jib. Some common counterweight materials include reinforced concrete and steel.

Why Don’t Tower Cranes Tip Over?

Have you ever looked up at a tower crane and noticed it seemed to be leaning? Your eyes aren’t deceiving you, but this isn’t necessarily a reason to be concerned. The steel used in the construction of a crane is strong and rigid, but even steel has some flexibility. The lean you are seeing is most likely due to that flex in the steel as the various loads are balanced against each other.

A tower crane, like most cranes, works on leverage and balance. One could say that a tower crane is a lever on top of a lever.

The jib and counter-jib serve as the first lever balancing the lifted load against the counterweights. If there is no load on the hook, the counterweights will cause the crane to be somewhat unbalanced towards the rear, and the crane will lean backward. As load is applied to the hook, the crane will gradually lean forward due to the shifting balance of the load vs. the counterweights. This is normal and expected. You could see several feet of movement at the top of the crane when lifting a heavy load with a tall crane.

Since the mass of counterweight is fixed, but the load being lifted varies greatly, there is usually some level of imbalance at the top of the crane. This imbalance results in a force at the top of the crane which is then balanced through the tower against the size and mass of the base. That is, the tower mast is essentially another lever.

Ultimately, the mass and size of the foundation is engineered to ensure the stability of the crane against these working loads & other factors.

Tower Crane Assembly and Dismantling

If the crane base is a concrete foundation, that will be poured as early as several weeks before the arrival of the crane to allow it to properly cure before assembly.

Once the crane arrives on site, the first thing to do is build the mast by stacking tower sections vertically. Once the mast is erected, the turntable is set on top of the mast and the horizontal components are added last (jib, counter jib, & counterweights).

All of the activities above require the use of an assist crane and adequate laydown area to build the crane components on the ground.

If necessary, a tower crane can climb itself to a taller height. To accomplish this, a climbing frame is typically installed at the top of the mast and connected to the turntable. The crane is then balanced, and the turntable is disconnected from the mast. The climbing frame will completely envelop multiple tower sections and, along with the balancing operation, ensures the top of the crane doesn’t fall off of the mast. At this point, the climbing frame uses hydraulic jacks to lift the top of the crane enough to insert another tower section at the top of the mast. This process can then be repeated to climb the crane higher.

For very tall projects, the tower crane may also be tied to the structure. Typically, tie-ins are installed as the structure increases in height and then followed by a climbing operation to increase the total height of the tower crane.

The disassembly process for a tower crane is essentially identical to the assembly process, but in reverse order.

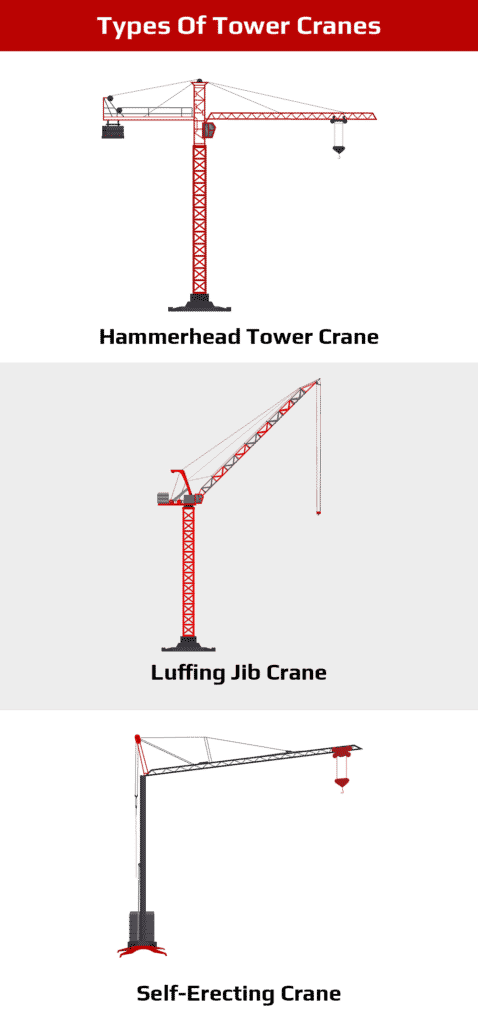

Types of Tower Cranes

There are as many tower crane types as there are lifting needs. Here’s a quick rundown of the most common tower crane styles used in construction sites.

Hammerhead Tower Crane

A hammerhead crane features a fixed, horizontal jib and a trolley assembly that travels the length of the jib to position the hook. Some hammerhead tower crane utilize pendant lines between the jib/counterjib and a tower top assembly while other utlize a “flat top” design without a tower top or pendant lines. Flat top tower cranes are especially useful in situations where multiple cranes swing through the same airspace.

Luffing Jib Crane

Often referred to as a luffer, this type of crane utilizes a jib that rotates up and down with the hook fixed to the end of the jib. The hook is positioned by luffing the jib up or down. This type of crane is especially useful on tight jobsites.

That is, a tower crane must be allowed to swing freely when not in use (weathervane). As such, a hammerhead crane requires a clear path around it equal to the full length of the jib. For example, if you needed 200’ of reach in a tower crane, but there was a 500’ tall high-rise 100’ away from the tower crane, you could not use a hammerhead for that application.

With a Luffing jib crane, the jib is set at a higher boom angle when not in use, which typically reduces the radius needed for weathervaning to less than half of the maximum possible reach.

Self-Erecting Crane

This is a smaller tower crane that can be erected on site without the absolute necessity of an assist crane. Typically, this type of crane will extend its mast and then unfold its jib via hydraulic cylinders permanently fixed to the crane. These cranes can not be tied to the structure and have limited hook heights available but are appropriate for smaller or shorter duration projects where the fixed costs assemble a more traditional “tower” are prohibitive.

Operating a Tower Crane

The majority of cranes feature a cab for the operator to sit in. Only a skilled and qualified operator can perform the job safely and prevent any unnecessary mishaps. Aside from the authorized driver, every construction site has a crane operating team. Each member assumes a different responsibility. This helps prevent minor incidents while performing the lifting maneuvers.

The crane coordinator or lift director is in charge of scheduling the lift. There’s also a signal person that becomes a second set of eyes to minimize the operator’s blind spots. This person will be available to communicate with the crane’s operator at all times.

Every day, the crane operator is responsible for performing pre-start check-ups to ensure the crane’s optimal functioning. Some vital components evaluated are the motors, wire ropes, safety devices, control systems, and the hook. If everything’s spot on, the operator can go on with their duties as initially planned. If not, immediate maintenance work is imperative.

Picking the Right Tower Crane

Each construction project has different needs when it comes to tools and materials. When selecting the most suitable tower crane for a project, you must always take the following factors into account:

Required Capacity

What do you need a crane for? If you’re not planning on lifting hefty materials or equipment regularly, a lightweight tower crane should do the trick. If there are only a few heavy picks to be made, it may be more cost effective to bring in a mobile crane for those picks and select a tower crane size more appropriate to the rest of the work.

Space Availability

One of the attractive features of a tower crane is that it takes up relatively little space on the ground. However, it does require a significant amount of space and support equipment on the ground to assemble and dismantle a tower crane. It is critical to assess not only the optimal location of the crane for the project, but also how it will get assembled and dismantled from that location.

Location

Remember, most tower cranes are static, which means that you will not be able to move them around as needed once installed. Plan ahead to ensure your crane will be able to reach where you need it to reach or consider complementing the tower crane with a mobile crane(s).

Load Capacity

Obviously, when selecting a crane one should consult the load charts to confirm the crane can lift the desired loads at the desired radii. Identifying both the heaviest lifts and longest reaches required is necessary to ensure the crane will be capable of doing the job. If there are only a limited number of heavy lifts required, it may be more cost effective to consider a smaller tower crane supported by mobile cranes as needed for those few heavier items.

The process of renting, transporting, and assembling a tower crane costs time, effort, and money. That’s a good enough reason always to double-check the load chart to see if the model you selected suits your particular lifting needs.

Best Projects for Tower Crane Use

Tower crane rental is a more affordable way to solve the lifting needs of any construction project. If you’re still unsure what you could use these powerful tools for, here are a couple of ideas:

- Hospitals and Educational Facilities

- Multi-Family Housing

- Water Treatment Facilities

- Parking Garages

- Mid/High Rise Construction

- Industrial Projects

Construction Power Reaching New Heights

Tower cranes have certainly come a long way since they first emerged in Europe. They provide solutions for many construction and lifting problems. These magnificent lifting powerhouses make work a lot more efficient, cost-effective, and sustainable. If you’re looking for tower crane rentals, have a look at Maxim Crane’s library of complimentary load charts to find the right crane for your next project.