The Historical Evolution of Construction Cranes

Construction cranes have been pivotal to architectural progress, with their origins tracing back to ancient Greece around 700 B.C.E. It was during this time that the Greeks, known for their engineering ingenuity, developed the earliest versions of these machines. This ancient innovation set the foundation for centuries of advancements and refinements in crane technology.

Subsequent civilizations built upon this Greek heritage, with the Egyptians integrating wooden cranes equipped with a rotating base, a cylindrical drum, and a sophisticated rope and pulley system. This allowed them to move massive stone blocks with more ease than ever before. As European architecture aspired to greater heights in the Middle Ages, cranes evolved yet again to include jibs, which enhanced their ability to construct monumental stone edifices.

The industrial revolution marked a transformative era for cranes, with steam-powered engines initially, and later electric motors, revolutionizing their capabilities. The introduction of steel in crane manufacturing not only increased their structural integrity but also significantly boosted their lifting capacities, thereby shaping the skyline of modern cities.

The Manufacturing Complexity of Modern Cranes

Modern construction cranes are marvels of engineering, embodying complex design principles and advanced manufacturing processes. The construction of these cranes is a sophisticated task that demands a deep understanding of physics and engineering. It’s not just about constructing a towering machine; it’s about creating a system that can safely and efficiently perform under the stresses of heavy lifting.

High-strength low alloy steel (HSLA) is the material of choice for crane production, prized for its exceptional durability and contribution to energy efficiency. The manufacturing process of cranes involves precision cutting of this robust steel, meticulous assembly of the various components, and secure joining through both bolting and welding.

Anatomy of a Construction Crane

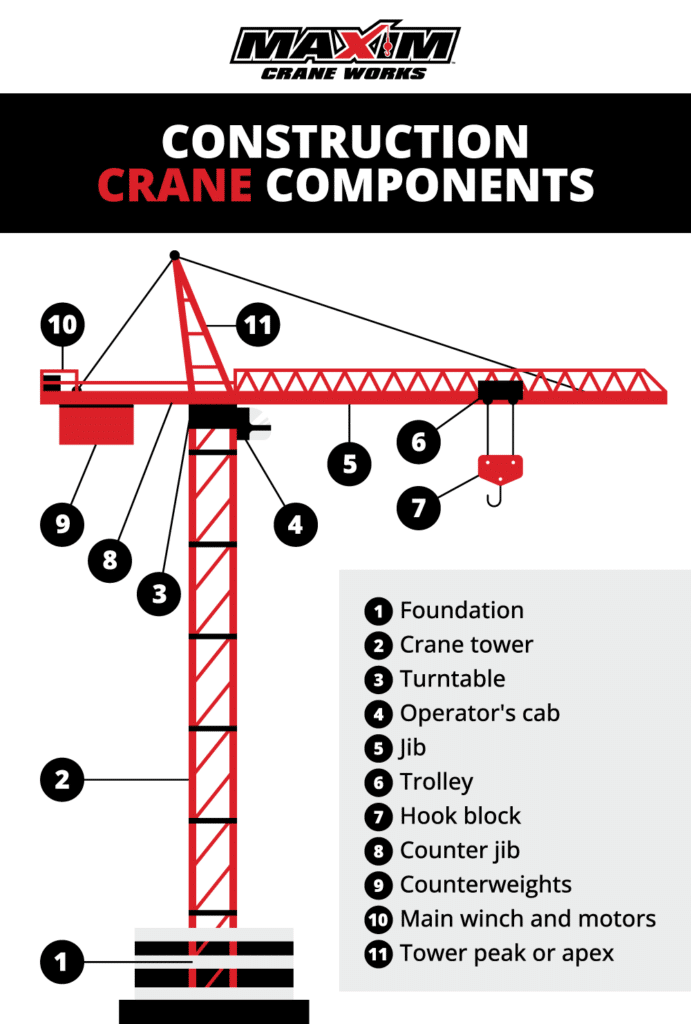

To appreciate the complexity of modern cranes, it’s crucial to understand their anatomy and the various components that work together to perform heavy lifting tasks efficiently. While this blog primarily focuses on cranes in general, in this example we will be highlighting the anatomy of a flat top or hammerhead tower crane. These specialized types of cranes are commonly used in construction projects and understanding its components is essential to appreciate the complexity of modern cranes.

The following are the key components of a tower crane:

- The foundation serves as the starting point for the stable operation of a construction crane. It is meticulously designed to support the immense weight of the crane and its loads, ensuring a secure anchorage to the ground.

- The crane tower, or mast, stands as the backbone of the structure, rising high above the construction site to give the crane its height and the ability to lift materials to considerable elevations.

- The turntable, central to the crane’s movement, facilitates full rotation, allowing the crane to access different angles around the site.

- Nestled within the turntable is the operator’s cab, from where the crane’s movements are meticulously controlled.

- The jib extends from the cab, functioning as the arm that reaches out to lift and transport materials.

- Equipped with a trolley and hook block, the system moves loads horizontally along the jib’s length.

- On the opposite end, the counter jib and counterweights maintain the crane’s balance, essential for the safe management of heavy loads.

- Powering these components are the main winch and motors, which drive the lifting and lowering of materials.

- The tower peak or apex, the highest section of the crane, supports the structural integrity of the crane’s uppermost portion.

Technological Advances in Crane Control Systems

Crane control systems have undergone significant technological enhancements to master the safe and efficient handling of loads.

- The sway control system (SCS) is a key innovation that mitigates the swinging of the load, this allows for smoother and more stable crane operation which can improve overall productivity on the construction site.

- The intuitive boom operating system (IBO), which facilitates precise movements and improves the operator’s control over the crane’s mechanisms. The IBO system helps operators to more accurately position loads, even in complex lifting scenarios.

- Cranes are equipped with load monitor indicators, critical for maintaining standards. These indicators alert operators if the load approaches the crane’s maximum capacity.

These technological developments have been instrumental in advancing crane functionality in modern construction.

Selecting the Right Crane for the Job

Selecting the appropriate crane for construction tasks is a critical decision that hinges on various factors, including the job’s specific requirements and the environment in which the crane will operate.

There are several types of cranes to choose from, such as:

- All-Terrain Cranes for their versatility and ease of transportation

- Hydraulic Truck Cranes for jobs that require frequent relocation

- Tower Cranes for their height and lifting capacity in urban construction

- Rough Terrain Cranes for stability on uneven surfaces

- Crawler Cranes for their mobility and heavy lifting capability on soft grounds

Maxim Crane’s team of professionals can provide guidance and support in selecting the most suitable crane for your project.

Furthermore, the skills of an experienced operator is critical to ensuring proper and efficient use of a crane. The operator’s knowledge and skills, combined with the crane’s capabilities, are essential for optimizing lifting operations.

Maxim Crane’s team of qualified and experienced operators are equipped to handle the most complex lifting tasks, providing clients with peace of mind and confidence in their crane operations.

Maxim Crane's Specialized Services in the Crane Industry

Maxim Crane stands at the forefront of the crane industry with a comprehensive suite of rental and lifting services. Their offerings are designed to accommodate the diverse needs of various construction projects, whether it’s a small-scale operation or a large, complex build. Maxim Crane has a strong focus on delivering solutions that align with client requirements.

Maxim Crane’s specialized heavy lifting services include:

- Rigging and Machinery Moving, utilizing state-of-the-art equipment and techniques to transport heavy machinery and equipment.

- Heavy Hauling, providing specialized transportation services for oversized or overweight loads.

- Industrial Plant Services, offering turnkey solutions for plant maintenance and shutdowns, encompassing everything from crane rental to equipment relocation.

- Infrastructure Construction, offering tailored solutions for bridge, power, and energy construction projects.

- Commercial Construction Services, providing solutions for high-rise buildings, stadiums, and other large-scale commercial construction projects.

With a commitment to innovation, and outstanding customer service, Maxim Crane has become a leader in the crane industry. Their extensive fleet of modern cranes is equipped to handle the most demanding lifting challenges, making them a trusted partner for any construction project.

The Importance of Professional Knowledge in Crane Operations

Professional knowledge is essential when it comes to crane operations for efficiency and compliance with industry standards. Guidance from seasoned professionals is invaluable for selecting the right crane and executing lifting tasks effectively.

Consulting with industry professionals like Maxim Crane is critical for project-specific crane use.

Elevating Projects with Maxim Crane

Understanding the complexities and capabilities of construction cranes is essential for any project aiming to rise above the ground. With the right type of crane and a knowledgeable operator, the sky’s the limit for what can be accomplished on a construction site.

As you consider the needs of your next big project, remember that not just any crane will do. You need a partner who can offer advice, reliable equipment, and a comprehensive approach to lifting solutions. At Maxim Crane, we pride ourselves on providing just that.

With our versatile fleet of cranes, we are equipped to handle the demands of any construction challenge. Trust us to elevate your project’s success with our industry-leading crane rental and heavy lifting services.

Reach out to Maxim Crane today to discuss your project needs and discover how our specialized rigging, heavy hauling, and state-of-the-art cranes can enhance your operations. Let’s lift your vision to new heights together.