The indisputable lifting champion when it comes to construction cranes is the almighty tower crane. Without it, some of the most iconic city skylines would look entirely different. Thinking about these construction site staples, most people can’t help but wonder how they can function.

Tower cranes’ tall and slender figure makes it hard to believe they can carry so much weight. If you’re curious about these marvels of the construction world, we’ve got you covered. Read on to answer all your tower crane-related questions once and for all.

The Evolution of the Tower Crane

Derrick tower cranes were the first tower cranes ever to see the light. Named after a type of gallows developed by Thomas Derrick, these lifting tools featured a boom attached to a rotating base with a hinge. Back then, there was no way to rent tower crane equipment. Construction crews had to come up with this type of ingenious lifting mechanism.

The early 20th century brought in a new design. Construction workers got tired of trying to maneuver large heavy equipment in denser urban areas. This led to the creation of the Gantry tower crane. Its tower featured suspended beams and trolleys. This model wasn’t that efficient, however, as the extra elements made it too heavy for most urban uses.

The tower crane we know and love appeared in 1949. The German Hans Liebherr conceived the machine to support post-war efforts to rebuild major cities. Liebherr’s design featured a rotating tower and horizontal working arm. It had a 360-degree range that made construction work much easier. Little did Liebherr know that his design would become a major inspiration for future prototypes.

In the 1970s, most manufacturers stopped making hydraulically powered tower cranes, switching to electric alternatives instead. Modern models have dozens of features that the crane operators of old could only dream of. Today, tower cranes are more powerful, versatile, and energy-efficient than ever.

Importance of Tower Cranes at the Construction Site

Tower cranes are indispensable assets for modern construction projects. These powerful machines enable construction companies to work faster, more efficiently, and handle heavy lifting with ease. Here’s why tower cranes are crucial at construction sites:

Enhanced Efficiency

Tower cranes significantly speed up construction processes by lifting and moving heavy materials quickly. This boosts productivity and reduces the time required for various construction phases.

Unmatched Lifting Capacity

These machines can lift extremely heavy loads that would be impossible for human labor alone. For example, they can move large items like steel beams, concrete blocks, and electrical generators effortlessly to any height.

Versatility in Building

Tower cranes are essential for constructing diverse structures such as skyscrapers, bridges, and elevated railways. Their ability to reach great heights and cover wide areas makes them perfect for urban development projects.

Energy Efficiency

By streamlining the transportation of materials on-site, tower cranes reduce the need for multiple machines and extensive manual labor. This not only cuts down on operational time but also contributes to a more energy-efficient construction process.

Precision

Tower cranes offer exceptional precision when positioning materials. This accuracy ensures that components are placed exactly where needed, which is crucial for maintaining the integrity and quality of the construction project.

Imagine a construction site without a tower crane. Modern advancements in architecture and engineering could grind to a halt, affecting everything from towering skyscrapers to essential infrastructure. The presence of tower cranes is a key factor behind the skyline of contemporary cities and the functionality of critical transportation networks.

Tower cranes have revolutionized the way we build, making them as foundational to construction sites today as the bricks and beams they lift.

How Do Tower Cranes Work?

Tower cranes are complex yet fascinating machines that play a vital role on construction sites. Here’s a detailed breakdown of how these towering giants operate:

Basic Mechanics of Tower Cranes

Tower cranes begin their operation by being bolted to a solid base, which can be a concrete pad or a steel structure, providing the necessary stability and anchoring for the crane. Rising from this strong base is the mast, a vertical structure constructed using steel lattice segments that are assembled on-site to achieve the required height. At the top of the mast, the turntable is installed and allows the jib, or the working arm, to rotate a full 360 degrees. The lifting hook, which is attached to the working arm through the trolley and hook block, moves horizontally along the jib and vertically to lift and position loads accurately.

Operating Components

The operator’s cab, where all the controls are located, is essential for managing the crane’s operations. Inside, operators use joysticks and computer systems to execute precise movements and ensure safe lifting. The jib stretches horizontally from the tower’s top and carries the load, while the counter jib, extending in the opposite direction, balances the crane’s weight distribution by mounting heavy counterweights. These counterweights, primarily made of reinforced concrete and steel, are crucial for maintaining the crane’s stability during operations.

Load Management

Load management in tower cranes relies heavily on precision and balance. The crane’s design, including its robust lattice structure and counterweights, ensures that tension is managed effectively during lifting operations. The trolley moves back and forth along the jib, positioning the load as needed, while the pulley system allows the hook and load to move up and down smoothly. Featuring a turntable, the crane gains a wide range of motion, which enables it to place loads precisely where needed on the construction site.

Understanding these core functions helps appreciate how tower cranes efficiently handle heavy lifting tasks, making them indispensable tools in modern construction.

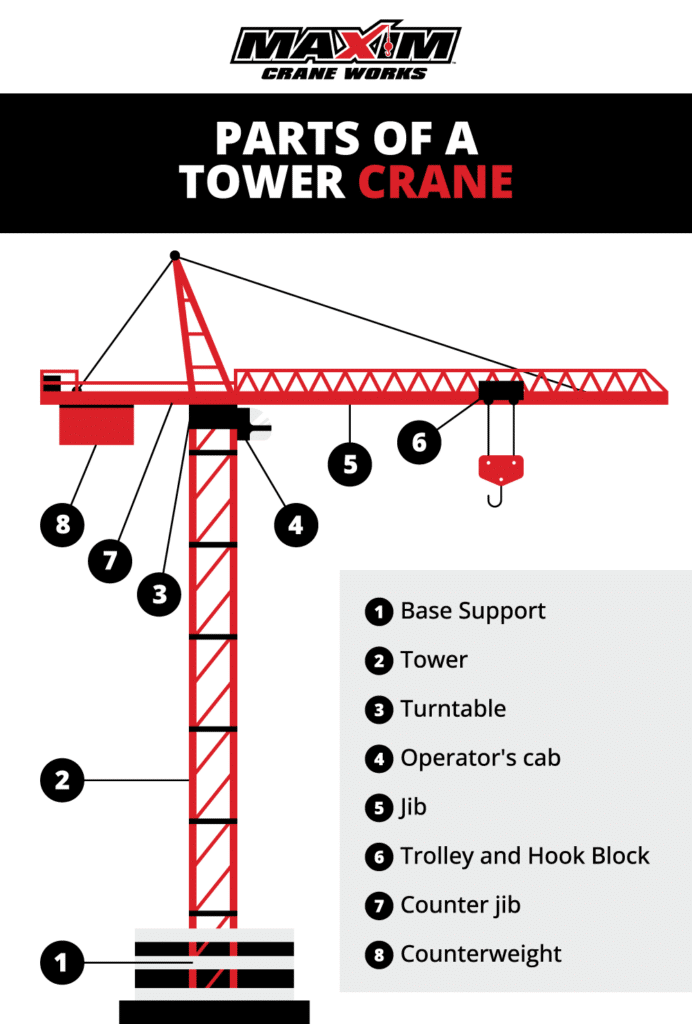

Parts of a Tower Crane

To fully grasp how tower cranes operate, it’s essential to understand their key components. Each part plays a vital role in the crane’s overall functionality and stability.

Base Support

The base support is the foundation of the tower crane, located at the bottom of the structure. It is typically attached to a concrete pad on the ground, providing a solid, stable base. In some cases, the base support may be connected to a steel grillage or a ballasted chassis, which can be placed on top of an existing structure or directly on the ground. This foundational element ensures the crane remains stable during operation.

Tower (Mast)

The tower, often referred to as the mast, is the vertical structure that gives the crane its impressive height. Extending from the base upwards, the tower supports crucial elements such as the operator’s cab, the hook, and the counterweights. It is constructed using steel lattice segments that provide additional strength and rigidity, allowing the crane to reach lofty heights without compromising stability.

Turntable

The turntable is a pivotal component of the tower crane, situated at the top of the mast. It enables the arm (jib) to rotate, giving the crane a broad range of motion. This mechanism uses technology similar to that found in windmills, allowing for smooth and precise rotation. The turntable is essential for positioning loads accurately across the construction site.

Operator's Cab

The operator’s cab is the control center of the crane. This enclosed space houses the operator along with the necessary control systems, including joysticks and computers, which are used to maneuver the crane. From this vantage point, the operator can execute complex lifting and positioning tasks with precision.

Jib (Working Arm)

Known as the working arm, the jib is the horizontal component that extends from the top of the tower. Its primary function is to support and position the load being lifted. The jib can extend outwards and move loads horizontally, providing flexibility in placing materials exactly where needed on the construction site.

Trolley and Hook Block

The trolley is a movable part that travels back and forth along the jib. Attached to the trolley is the hook block, which functions as a pulley system. This arrangement allows the hook to travel vertically up and down the tower, facilitating the lifting and lowering of loads. The combination of the trolley and hook block is crucial for the precise movement of materials.

Counter Jib

The counter jib is the horizontal arm that extends in the opposite direction of the jib. Its role is to help balance the crane by counteracting the weight of the load being lifted. The counter jib also serves as the mounting point for the counterweights, which are essential for maintaining the crane’s stability during operations.

Counterweight

Counterweights are critical components that balance the crane during lifting tasks. Located at the rear of the counter jib, these weights counteract the load being lifted on the jib. Without counterweights, the crane’s load capacity would be significantly reduced to ensure stability. Common materials used for counterweights include reinforced concrete and steel, providing the necessary heft to keep the crane balanced.

Each of these components works in harmony to make tower cranes indispensable tools for construction projects, enabling heavy lifting and precise placement of materials at significant heights.

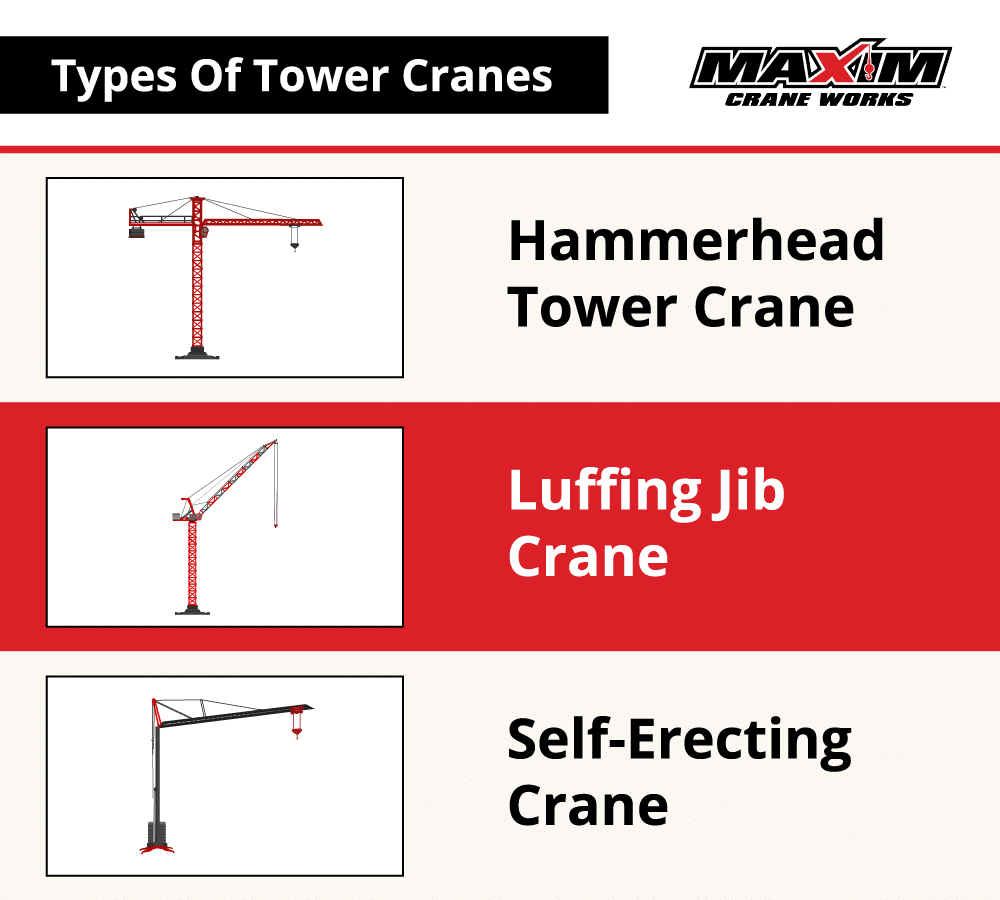

Types of Tower Cranes

There are as many tower crane types as there are lifting needs. Here’s a quick rundown of the most common tower crane styles used in construction sites.

Hammerhead Tower Crane

A hammerhead crane features a fixed, horizontal jib and a trolley assembly that travels the length of the jib to position the hook. Some hammerhead tower cranes utilize pendant lines between the jib/counter jib and a tower top assembly while others utilize a “flat top” design without a tower top or pendant lines. Flat top tower cranes are especially useful in situations where multiple cranes swing through the same airspace.

Luffing Jib Crane

Often referred to as a luffer, this type of crane utilizes a jib that rotates up and down with the hook fixed to the end of the jib. The hook is positioned by luffing the jib up or down. This type of crane is especially useful on tight jobsites.

Self-Erecting Crane

This is a smaller tower crane that can be erected on site without the absolute necessity of an assist crane. Typically, this type of crane will extend its mast and then unfold its jib via hydraulic cylinders permanently fixed to the crane. These cranes can not be tied to the structure and have limited hook heights available but are appropriate for smaller or shorter duration projects where the fixed costs assemble a more traditional “tower” are prohibitive.

Selecting the Right Tower Crane for Your Project

Each construction project has unique requirements for tools and materials. Selecting the most suitable tower crane involves considering several critical factors. Maxim Crane Works offers assistance to help you choose the right crane for your specific needs, ensuring your project runs smoothly and efficiently.

Required Capacity

Determine the primary purpose of the crane. If your project involves lifting lightweight materials or equipment, a smaller tower crane may be sufficient. For projects requiring occasional heavy lifts, it might be more cost-effective to supplement a smaller tower crane with a mobile crane for those specific tasks. Maxim Crane can provide a thorough assessment of your lifting needs and recommend the ideal crane configuration.

Space Availability

While tower cranes take up relatively little ground space, their assembly and dismantling require significant room and support equipment. Maxim Crane’s team can help you assess the optimal location for your crane and plan for the necessary space to assemble and dismantle it. They’ll ensure that your crane setup is efficient and minimally disruptive to your construction site.

Location

Most tower cranes are static and cannot be moved once installed. Therefore, it’s crucial to plan the crane’s location meticulously. The crane must be able to reach all areas where lifting is required. Maxim Crane’s knowledgeable team can help you evaluate whether a static tower crane will suffice or if your project would benefit from supplemental mobile cranes to cover additional areas.

Load Capacity

Consulting load charts is essential to verify that the selected crane can handle the desired loads at the needed radii. Identifying both the heaviest lifts and the longest reaches required ensures the crane can perform the necessary tasks. For projects with only a few heavy lifts, it might be more economical to use a smaller tower crane augmented by mobile cranes for those specific heavy items. Maxim Crane can assist you in analyzing load charts and selecting the most efficient crane setup.

Renting, transporting, and assembling a tower crane involves significant time, effort, and expense. Maxim Crane provides end-to-end services, including planning, transportation, and assembly, to optimize your crane’s performance and reduce overall costs. By collaborating with Maxim Crane, you can know that the crane selected meets all your project’s lifting requirements effectively and economically.

Ideal Uses and Projects for Tower Cranes

Tower cranes are indispensable tools for construction sites worldwide, recognized for their towering height and impressive lifting capabilities. They are especially useful for projects requiring heavy lifting at extreme heights. Given the high cost of purchasing a tower crane, many contractors opt for renting these colossal machines to meet their project needs more affordably.

Tower cranes are utilized for lifting steel, concrete, and other heavy materials, providing an efficient alternative to manually transporting bulky equipment. Their use is not only practical but also contributes to the iconic urban skyline.

Here are some ideal projects where renting a tower crane can be particularly beneficial:

Hospitals and Educational Facilities

Constructing hospitals and educational facilities often involves installing substantial amounts of heavy equipment and materials. These structures typically require advanced medical machinery, large HVAC systems, and significant amounts of structural steel and concrete. Tower cranes efficiently handle these heavy lifts, allowing for the safe and timely placement of critical components at the necessary heights. Their precise control ensures that essential installations are completed with minimal disruption to surrounding areas.

Multi-Family Housing

Erecting apartment complexes and other multi-family dwellings comes with the constant need for lifting heavy building materials like steel beams, concrete slabs, and prefabricated panels. Tower cranes excel in such environments, providing the necessary height and reach to place materials accurately within densely packed construction zones. Their ability to handle substantial loads means quicker and more efficient construction processes, ultimately saving time and reducing overall project costs.

Water Treatment Facilities

Building water treatment plants involves the installation of large tanks, extensive piping systems, and other heavy components. These elements are often cumbersome and difficult to move manually. Tower cranes streamline this process by lifting and positioning these heavy and unwieldy items with ease. This helps to ensure that construction progresses smoothly, adhering to project timelines. The cranes’ versatility also accommodates the varying height and reach requirements of different components within the facility.

Parking Garages

Multi-level parking structures require precise and heavy lifting capabilities to position concrete panels, steel reinforcements, and other structural elements accurately. The confined nature of these projects makes the tower crane’s reach and maneuverability particularly valuable. By efficiently managing heavy loads, tower cranes help expedite the construction process, allowing for quicker completion times and a seamless transition to the next phases of development.

Mid/High Rise Construction

Tower cranes are quintessential for mid-rise and high-rise building projects. These cranes enable the lifting of materials to great heights, allowing for the smooth and efficient construction of tall structures. From steel frameworks to building facades and interior installations, tower cranes handle the heavy lifting required at various stages of high-rise construction. Their ability to reach higher floors ensures that all materials are delivered precisely where needed, enhancing jobsite productivity.

Industrial Projects

Industrial construction projects, such as factories, warehouses, and manufacturing facilities, involve the assembly and installation of heavy machinery, large structural components, and extensive building materials. Tower cranes are ideal for these projects due to their impressive lifting capacity and versatility. They facilitate the installation of oversized industrial equipment, structural steel, and other essential materials, ensuring that the construction process remains efficient and within budget.

Maxim Crane offers a wide range of tower crane rentals, perfect for various applications. Their crane professionals can assist you in selecting the right crane for your project, ensuring you have the ideal equipment to meet your lifting needs efficiently and cost-effectively. With Maxim Crane’s comprehensive services, including planning, transportation, and assembly, you can be confident that your project will benefit from the best tower crane solutions available.

Construction Power Reaching New Heights

Tower cranes have evolved significantly since their inception in Europe, now serving as essential solutions for a variety of construction and lifting challenges. These magnificent lifting powerhouses enhance efficiency, reduce costs, and promote sustainability on construction sites.

For your tower crane rental needs, explore Maxim Crane’s extensive library of complimentary load charts to find the perfect crane for your next project. Maxim Crane’s knowledgeable team is ready to assist you in selecting the right equipment to ensure your project reaches new heights of success.