For businesses in construction, industrial development, and infrastructure, selecting the right heavy equipment is critical for project success. While brand-new cranes offer the latest technology and pristine condition, used cranes present a cost-effective alternative with reliable performance and proven operational efficiency. This article explores the tangible advantages of purchasing used cranes and provides strategic guidance for making a confident, informed buying decision. In doing so, it also highlights how Maxim Crane stands out as a knowledgeable partner, offering a wide variety of quality equipment options.

Understanding the Value of Investing in Used Cranes

Used cranes are simply cranes that have been previously owned and operated, often with a substantial remaining service life. Many cranes in the used-equipment market come from businesses rotating or downsizing their fleets, leaving highly functional units available for resale. This dynamic creates opportunities for buyers to acquire machinery that has already been tested in real-world conditions.

In the United States, the market for used heavy equipment continues to grow, especially as companies seek to optimize capital expenditure. According to industry data, construction firms and industrial entities frequently choose pre-owned cranes to maintain productivity without incurring the higher initial cost of a fully new machine. By focusing on equipment age, documented service history, and overall condition, buyers can secure dependable assets at a more attractive price point.

Moreover, these benefits aren’t limited to smaller contractors with leaner budgets. Large-scale construction companies also turn to used cranes to supplement existing fleets during peak periods. Major projects—such as commercial complexes, industrial expansions, and infrastructure revitalizations—can require additional lifting capacity at various project phases. Instead of purchasing brand-new units, many opt for used cranes that can be deployed quickly and cost-effectively. This flexibility helps align project timelines with budget constraints, supporting a balanced approach to allocating resources.

In addition, buyers can look into how well the crane has withstood different operational contexts. A crane used in a moderate climate, for instance, may have less body or component wear compared to one that has operated in harsh winter conditions. By examining these factors, businesses reinforce their ability to identify machines that match project requirements more precisely. IBISWorld reports that the Overhead Crane Manufacturing industry—covering cranes and hoists—has experienced steady and sustained demand, underscoring that well-maintained pre-owned equipment remains a valuable and dependable asset for many firms

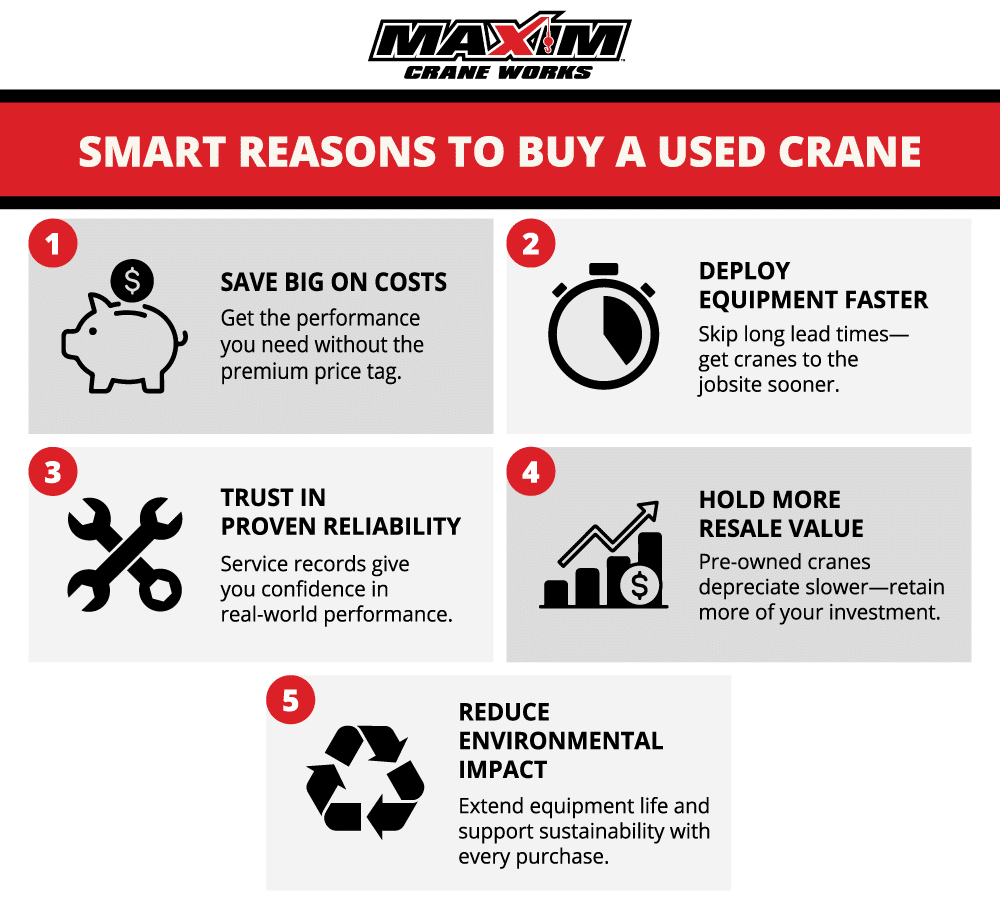

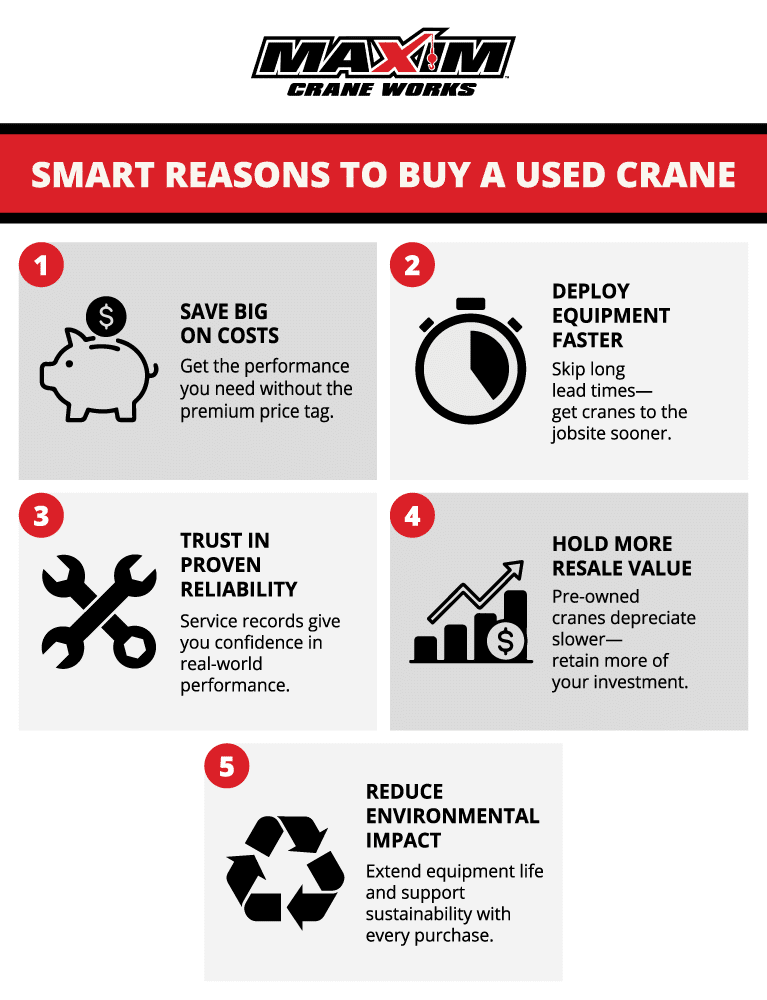

Advantages of Buying Used Cranes

Purchasing used cranes provides multiple advantages, ranging from lower expenses to an established performance record. Below are notable benefits:

Significant Cost Savings

Pre-owned cranes come at a reduced cost compared to new models. Avoiding the initial depreciation also means that buyers can allocate their funds elsewhere, such as additional attachments or project-specific equipment. According to insights from Kaizen, cost savings strategies are particularly relevant in construction, among the most budget-sensitive industries. By paying less upfront, buyers are positioned to manage projects with greater financial flexibility.

Faster Accessibility

Used cranes typically shorten the timeline for acquiring necessary heavy machinery. New equipment sometimes involves lengthy production backlogs and transportation arrangements. With a used unit, the purchase process can often be completed more rapidly, allowing businesses to meet project milestones promptly. Reducing wait times is especially helpful for contractors who need immediate solutions to fulfill sudden workload increases.

Proven Performance

Pre-owned cranes often come with extensive service records, offering a clear picture of previous operational results. Knowing how a crane has performed under real conditions helps buyers assess whether it can continue to function effectively. Having proof of maintenance activities also provides a sense of reliability. While brand-new equipment may require initial run-in and testing, used cranes demonstrate performance benchmarks grounded in actual project usage.

Strong Resale Value

Much of a crane’s depreciation happens in its early years. A well-maintained used crane, therefore, may hold its worth for a longer period. Businesses that eventually upgrade or alter their fleets can find that a pre-owned unit is easier to resell without steep losses. Documentation and maintenance logs can reinforce resale prospects, as they convey the machine’s condition to potential buyers more transparently.

Environmental Benefits

Reusing heavy equipment contributes to sustainability goals by extending the overall lifecycle of a machine. Purchasing a crane that still has productive years left lowers the demand on new manufacturing processes and the raw materials they consume. For companies aiming to reduce their environmental footprint, incorporating used cranes ranks as an eco-friendly and financially prudent strategy.

Practical Applications of Cost-Effective Heavy Machinery

Used cranes fill a variety of roles across construction, infrastructure, and industrial environments. Their adaptability unlocks opportunities for businesses of differing sizes:

- Commercial construction projects often rely on used cranes to lift building materials like steel beams, pre-cast concrete, and modular units. These projects have strict deadlines, and acquiring a crane quickly under budget constraints can prevent delays.

- Industrial facilities frequently integrate used cranes into maintenance programs or expansions. For example, manufacturing plants undergoing upgrades may require robust lifting solutions temporarily. Pre-owned cranes fill that gap without straining funds needed for core production improvements.

- Infrastructure initiatives—including road expansions, bridge construction, and large-scale public works—make use of used cranes to handle heavy components. By reducing initial costs on equipment, agencies or contractors can allocate more resources to labor or advanced materials.

Smaller businesses or niche contractors can also benefit from used machinery as they scale up. Buying a pre-owned crane at a lower price point allows them to compete for larger contracts, close capability gaps, and upgrade operational capacities. When looking for appropriate models, many businesses discover that Maxim Crane maintains a diverse inventory with options like all-terrain cranes and rough-terrain cranes. These selections support a wide variety of lifting tasks, enabling businesses to match specific crane types to specialized project demands.

Beyond the type of crane, understanding how each model is suited to different work sites is also essential. Some organizations may operate mainly in urban environments with flat terrain, while others deal with uneven ground and harsh conditions. Purchasing a used crane that has documented success in a similar environment can streamline the process of mobilizing equipment efficiently.

Factors to Consider When Purchasing Used Cranes

Selecting a used crane goes beyond the upfront price. Prospective buyers should conduct a thoughtful evaluation to avoid future complications:

Assess the Equipment’s Overall Condition

Examining a crane’s key systems, such as booms and load-bearing structures, helps confirm that the machinery is in good shape. Requesting detailed service logs and maintenance records from the seller is a common approach to verifying historical upkeep. Some buyers also conduct operational tests or contact independent inspectors to confirm that the crane can perform under typical project conditions.

Match Specifications to Project Requirements

Making certain that a crane’s lifting capacity, boom length, and mobility correspond to functional needs prevents possible downtime. Different crane types are designed for distinct tasks: all-terrain cranes for mixed ground conditions, rough-terrain cranes for job sites with uneven surfaces, and crawler cranes for heavy loads that need stable ground contact. By matching specifications precisely, companies can reduce the likelihood of equipment modifications later.

Consider Parts Availability and Aftermarket Support

Long-term operation heavily depends on the availability of parts. When evaluating used equipment, buyers should confirm that needed components can be sourced promptly. Spare parts availability is especially critical if a crane model has been discontinued, or if the original manufacturer changed product lines. Having a reliable vendor or dealer for aftermarket support can simplify ongoing maintenance.

Evaluate the Sellers Reputation

Reputable dealers or sellers normally provide transparent documentation that covers operating history, repairs, and upgrades. They may also offer post-sale services such as engineering advice for complex lifting tasks. Checking user experiences, online feedback, or industry accreditations can help buyers filter out less reliable vendors.

Conduct Thorough Physical Inspections

Before finalizing any purchase, an in-person inspection is highly valuable. Detailed examinations confirm that no hidden issues compromise the equipment’s integrity. Bringing along an experienced mechanic or engineer can piece together an accurate understanding of the crane’s current state. Similar to general heavy-equipment best practices, physical inspections validate the unit’s reliability before significant capital is spent.

Practical Tips for Buying Used Cranes

A well-rounded purchase strategy enhances the return on investment and the overall functionality of a used crane. Here are some guidelines:

Establish Your Budget and Define Requirements

Start by outlining both your target budget and the major parameters you require, such as load capacity, boom reach, and on-road/off-road hauling possibilities. This upfront clarity helps narrow down unnecessary options and centers your attention on viable machines.

Choose Reliable Vendors

Working with trustworthy vendors or dealers is one of the most direct ways to reduce guesswork. Providers with a well-established reputation for honesty and quality help confirm that you obtain a crane in good operating condition. They may also supply additional insights regarding local regulations or specialized features relevant to your project’s scope.

Conduct Thorough Inspections

Even if a crane’s paperwork appears comprehensive, a physical evaluation remains fundamental. Testing core mechanical systems, such as hydraulic functions and telescoping booms, can reveal issues that might otherwise remain overlooked. Including a qualified professional in this step is beneficial, as they can identify subtle warning signs.

Verify Parts and Support Availability

Confirm that the specific crane model has adequate parts support in the market. If certain components are scarce or require long shipping times, project schedules can be disrupted. Understanding how quickly you can address potential mechanical problems helps sustain productivity levels over the crane’s operational lifespan.

Perform a Long-Term Cost Analysis

Calculating the overall lifecycle cost helps clarify whether the return on investment justifies the expense. Along with the purchase price, factor in routine maintenance, probable repairs, and the potential for future modifications. This comprehensive financial view aids in determining if the selected crane is likely to be a successful long-range asset.

For buyers seeking a broad selection, reviewing a used crane inventory can offer insights into the variety of models and configurations available.

Maximizing ROI: Strategies for Operational Excellence with Used Cranes

Simply acquiring a used crane is only part of the equation. Extracting the most value from the machine requires an ongoing, deliberate operational plan:

- Schedule periodic performance audits. Tracking fuel consumption and analyzing lift cycles can highlight areas to refine. Over time, this approach improves day-to-day efficiencies and extends equipment longevity.

- Train in-house teams for proactive maintenance. When technical staff promptly address minor repairs, the crane remains in better operating condition. This method also minimizes extended downtimes that can disrupt project timelines.

- Use asset management systems to organize upkeep. Digital tools can create alerts for periodic inspections, helping owners stay current on preventative measures. Early detection of potential issues leads to more cost-effective resolutions.

- Collaborate with experienced vendors to explore enhancements. Beyond basic upkeep, some older machines are good candidates for upgrades or retrofits that improve performance. Through such relationships, businesses can keep equipment relevant and capable for changing project demands.

Additionally, it helps to maintain clear records of how the crane is used over time. Comprehensive documentation, including logged hours of operation, maintenance intervals, and parts replacements, not only aids internal management but also helps preserve resale value. If you eventually decide to sell or trade the crane, prospective buyers will appreciate transparent reporting, allowing them to make a faster and more confident purchasing decision.

Future Market Trends and Strategic Considerations

As market conditions shift, interest in used cranes is on the rise for several reasons. Demand for budget-friendly alternatives often grows when economic uncertainty prompts cost-conscious purchasing decisions. Infrastructure programs, frequently driven by large-scale public funding, also spur interest in used equipment. Contractors aim to balance meeting completion deadlines with keeping expenses manageable.

Technological advances in diagnostics are further boosting the appeal of pre-owned machinery. Modern scanning methods and condition-monitoring tools provide deeper insight into crane components, making it simpler to project a crane’s lifespan. As a result, companies can weigh data on operating temperature, fluid analysis, and component stress. These developments reduce guesswork and create a more transparent used-equipment market.

During strategic planning sessions, many businesses allow for both new and used crane acquisitions. This hybrid approach forms a flexible fleet that can swiftly adapt to changing workloads. Used cranes, in particular, can fill gaps when unexpected demand spikes, allowing projects to progress on schedule without expanding capital expenditures excessively. Insights from renting construction equipment strategies further show that businesses able to pivot between owning and leasing equipment see more consistent budget management.

Expanding Use Cases Through Technology

Emerging software platforms are helping contractors better analyze job site requirements, which can guide them toward optimal crane choices. In some instances, a used all-terrain crane might outperform a newer but smaller rough-terrain model, simply because its performance metrics align more effectively with the specific tasks at hand. This evidence-based selection process elevates the usefulness of the pre-owned equipment market, confirming that machines are well-matched to each scenario.

Growth of Sustainability Initiatives

Meanwhile, many industries strive to adopt greener methods by reevaluating how resources are acquired and utilized. Opting for used cranes is an example of extending machine lifecycles, diminishing the environmental impact of manufacturing new units. In certain cases, adding modern attachments or integrating advanced controls onto a pre-owned crane can enhance efficiency, supporting sustainability targets while preserving capital.

Emerging Financing and Leasing Options

Financing and leasing alternatives continue to evolve, adding another layer of appeal to used crane acquisitions. Buyers can often secure leases with shorter durations, giving them the flexibility to align project timelines with payment structures. Some companies require a crane only for a brief period—perhaps a major site expansion or a sudden contract that demands additional lifting capacity. Rather than purchasing a high-value piece of machinery outright, businesses might opt for flexible payment terms that reduce the immediate burden on cash flow.

Indeed, engaging in these financing routes allows for more accurate project budgeting. If the crane will only be necessary for a specific phase, a short-term lease caps the financial commitment. This approach levels out expenses and can be combined with data-driven decisions on the best time to purchase versus lease. Insights from engineering services by Maxim Crane and rigging solutions also highlight how strategic partnerships, combined with flexible equipment acquisition, contribute to smoother operations.

Why Consider Used Cranes for Sale from Providers Like Maxim Crane

Selecting a reputable provider for used cranes can simplify the entire acquisition process. Maxim Crane, recognized for its broad industry experience, offers a range of pre-owned cranes that have been carefully assessed for quality and performance. Some of the benefits of working with an established partner include:

- Access to a large inventory of crane models, suited to commercial, infrastructure, and industrial projects.

- Transparent service histories and thorough documentation that give insights into a crane’s operational background.

- Extensive knowledge in project-specific engineering, aligning the crane’s specs with on-site requirements.

- Assistance in choosing between similar crane models, considering factors like hours of operation, attachment configurations, and crane capacity.

- Experienced advisors who can pinpoint which crane models are best suited to specific environments and project demands.

Maxim Crane also offers rental options for companies that need equipment for a specific project. By working with a knowledgeable provider, companies can also gain insights into market trends and emerging technologies.collaborating with skilled professionals in heavy lifting can help you anticipate which configurations and attachments might be most advantageous. This level of guidance supports more accurate project planning and can assist companies as they adapt to emerging market trends.

Embrace the Future of Construction with Used Cranes

Investing in used cranes offers a powerful blend of cost efficiency, proven performance, and long-term flexibility—attributes that resonate with businesses across construction, industrial manufacturing, and infrastructure. A well-maintained pre-owned crane can meet exact operational needs while allowing companies to manage budgets responsibly.

To learn more about finding a crane that aligns with your upcoming projects or expanding your fleet with reliable pre-owned equipment, visit Maxim Crane Marketplace and explore the diverse selection of used cranes available. Whether you require better lifting capacity for ongoing construction or you’re preparing for a future project, partnering with a trusted industry resource can transform your equipment investment into a strategic advantage.