Carry deck cranes are essential tools in construction, industrial maintenance, and specialized projects. At Maxim Crane Works, we offer a diverse fleet of carry deck cranes to meet various lifting and transporting needs. Renowned for their compact design, mobility, and multifunctional capabilities, these cranes excel in projects with space constraints and demanding requirements.

In this blog, we’ll define carry deck cranes, look at their evolution from “pick and carry” models to today’s advanced machines, and highlight the types of projects best suited for carry deck cranes, from construction and industrial maintenance to utilities and infrastructure.

Whether you’re in construction, industrial, or maintenance sectors, understanding the advantages and applications of carry deck cranes can enhance your project’s efficiency and safety. Explore how these versatile machines can benefit your lifting and transporting needs.

What Is a Carry Deck Crane?

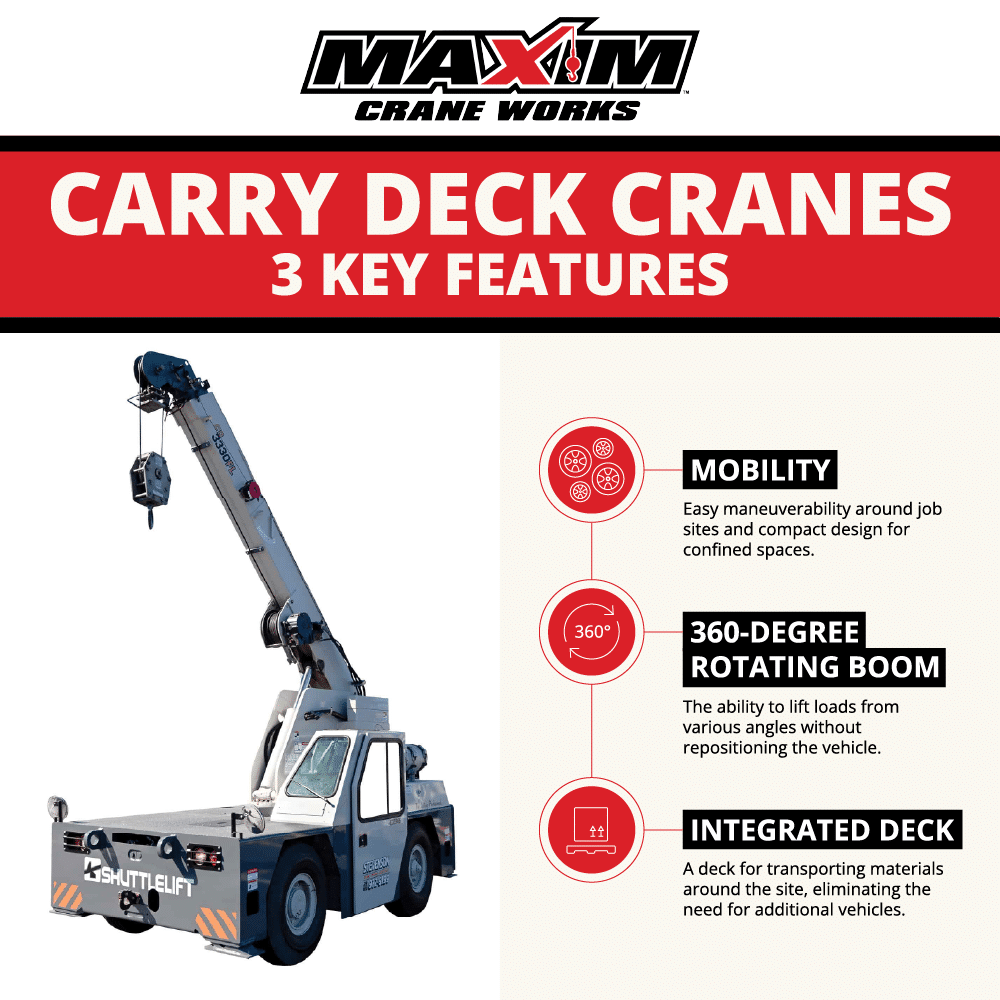

Carry deck cranes are among the most versatile and compact lifting machines available, specifically designed to navigate tight spaces and handle various lifting tasks with ease. These cranes are characterized by their wheeled design, allowing for excellent mobility, and their 360-degree rotating boom, which provides unparalleled flexibility in lifting operations.

They also feature an integrated deck, allowing for the transportation of materials across job sites without the need for additional vehicles. This unique combination of attributes makes carry deck cranes an essential tool for a wide range of applications, from construction and industrial projects to maintenance and repair tasks.

Key Features of Carry Deck Cranes

- Mobility: Carry deck cranes are wheeled, allowing them to maneuver easily around job sites. They do not require large clearances or pre-laid tracks, enabling them to drive around like a truck. Their compact size enhances their agility, especially in confined spaces.

- Rotating Boom: Equipped with a 360-degree rotating boom, carry deck cranes can handle loads from various angles, offering flexibility and precision without needing to reposition the entire vehicle.

- Integrated Deck: The deck is a defining feature, offering a platform to transport materials around the job site. This built-in capability eliminates the need for additional vehicles for material transport.

Versatility and Efficiency

- Multi-functional: Despite their smaller size, carry deck cranes can perform a variety of tasks, effectively replacing multiple pieces of larger equipment on smaller job sites. They are capable of lifting, lowering, and transporting materials, offering a comprehensive solution for diverse job site requirements.

- Single Operator: One of the significant advantages of most carry deck cranes is that they typically require only one operator. This simplicity not only eases the operation but also reduces labor costs and coordination efforts, streamlining the workflow on the job site.

- Space Optimization: Their compact design is a standout feature, allowing them to operate efficiently in tight and confined spaces. This makes them particularly beneficial for urban construction sites or areas with limited access, where larger cranes would struggle to perform.

Carry deck cranes offer an excellent balance of mobility, versatility, and efficiency, making them an invaluable asset for various lifting tasks on compact and busy job sites.

How Does a Carry Deck Crane Work?

A carry deck crane is more than just a truck with a lifting boom. These machines have specialized components that enable them to transport and lift materials efficiently around job sites. Here are the elements that make carry deck cranes stand out:

Self-loading Carry Decks

A defining feature of carry deck cranes is their self-loading carry decks. Unlike simple transport vehicles, these cranes can load and unload materials onto their decks autonomously. This self-loading capability is crucial for job site efficiency, as it allows the crane to place cargo onto its deck and remove it at different locations without requiring additional equipment or personnel.

Fully Hydraulic Controls

Carry deck cranes are equipped with fully hydraulic controls, which provide the operator with precise control over lifting and movement operations. Designed for single-person operation, these hydraulic systems enable pinpoint accuracy in positioning loads. This level of control is essential for safely maneuvering materials in tight or crowded job sites where precision is key.

Outriggers for Stability

Outriggers are an essential component of carry deck cranes, ensuring stability during lifting operations. While rubber wheels offer excellent mobility, they are not sufficient for maintaining balance when the crane is lifting heavy objects. Outriggers extend from the crane to provide a stable base, allowing the machine to handle heavier loads with confidence. This added stability is crucial for maintaining safety and efficiency on the job site.

Load Capacity

The load capacity of carry deck cranes varies by model and specific application. These cranes are designed to handle a wide range of lifting tasks, but it’s important to consult the load charts specific to each model to understand their capacity limits. Generally, carry deck cranes have a significant lifting capacity, although the transport capacity on the deck may be lower due to the weight resting entirely on the wheels.

Integrated Counterweights

Counterweights are built into carry deck cranes to help to ensure stability and balance during lifting and pivoting operations. Unlike other types of cranes that require manual setup of counterweights, carry deck cranes have these counterweights integrated into the design. This feature simplifies setup and enhances safety, making the crane more efficient to operate.

Weight and Compact Design

The weight of a carry deck crane depends on its size and load capacity. These cranes typically weigh between 3 to 30 tons, depending on the model. Despite their relatively compact size, carry deck cranes can lift more than cranes of similar weights, thanks to their robust design and integrated counterweights. Their compact design also allows them to maneuver and operate in confined spaces, making them ideal for urban construction sites or areas with limited access.

Carry deck cranes incorporate these specialized components to deliver a versatile, efficient, and reliable lifting solution, making them an invaluable asset for various job site applications.

Carry Deck Cranes Over the Years

Carry deck cranes have undergone significant transformations over the past few decades. The journey began with the introduction of the “pick and carry” model, the first cranes designed to transport loads while moving. Appearing in the 1980s, these cranes were primarily used to move small loads around job sites, keeping their cargo suspended in the air during transit.

However, the pick and carry cranes had limitations. The danger of leaving loads suspended, particularly with heavier materials, quickly became apparent. The instability and risk associated with swinging loads and potential overbalancing necessitated a safer, more efficient solution.

The carry deck crane emerged as an evolutionary advancement of the pick and carry model. Unlike its predecessor, the carry deck crane is designed with an integrated deck for placing materials. By setting loads on the crane’s main body, these machines effectively lower the center of gravity, enhancing stability and safety. This design minimizes the risks associated with swinging loads and overbalancing, allowing for the safe transportation of heavier weights.

Today, carry deck cranes have largely replaced pick and carry models in many applications. Their ability to securely transport materials on the deck, combined with enhanced stability and versatility, makes carry deck cranes a preferred choice for various lifting tasks across numerous job sites.

Ideal Projects for Carry Deck Cranes

Carry deck cranes are versatile machines that excel in a variety of project environments, thanks to their compact size, mobility, and multifunctionality. Here are some of the types of projects where carry deck cranes are best suited:

Construction Sites

Carry deck cranes are indispensable on construction sites, especially those with space constraints. Their compact design allows them to navigate tight areas, maneuver through narrow spaces, and operate underneath overhead obstacles. This makes them ideal for:

- Urban construction projects with limited space

- Residential building sites

- Interior construction tasks where larger cranes cannot fit

Industrial Maintenance

In industrial settings, carry deck cranes are frequently used for maintenance and equipment movement. They can easily access hard-to-reach areas within factories or plants, providing:

- Efficient relocation of machinery and equipment

- Routine maintenance tasks such as replacing parts or lifting materials

- Emergency repairs that require quick and precise lifting solutions

Utilities and Infrastructure Projects

Utility and infrastructure projects often involve complex and confined work environments. Carry deck cranes are suitable for:

- Power plant maintenance and upgrades

- Water treatment facility repairs

- Bridge and overpass construction where mobility and compactness are crucial

Storage and Warehousing

For storage facilities and warehousing projects, carry deck cranes offer a flexible solution for moving heavy items. They can efficiently perform tasks such as:

- Loading and unloading shipments

- Reorganizing heavy inventory within crowded warehouse spaces

- Transporting large, bulky items between different sections of a storage area

Manufacturing Plants

Manufacturing plants often require the precise positioning of materials and equipment. Carry deck cranes can easily handle:

- Intra-plant material transport

- Equipment installation and removal

- Reconfiguring production lines to optimize workflow

Shipyards and Dockyards

In shipyards and dockyards, carry deck cranes are valuable for their ability to operate in tight spaces. They can be used for:

- Loading and unloading ship components

- Repairing sections of a vessel in restricted areas

- Transporting materials between different points within the dockyard

Carry deck cranes are suitable for a wide range of projects requiring compact, mobile, and versatile lifting solutions. Their ability to operate efficiently in confined spaces while performing multiple tasks makes them a valuable asset in various industries.

Renting a Carry Deck Crane with Maxim: Your Partner in Success

Carry deck cranes are versatile and invaluable tools across numerous industries, offering unparalleled agility and efficiency in tight and demanding environments. At Maxim Crane Works, we provide an extensive fleet of carry deck cranes designed to meet a wide range of project requirements. Whether you’re engaged in urban construction, industrial maintenance, or utility work, our cranes are equipped to handle your most challenging tasks.

When you choose to rent a carry deck crane from Maxim Crane Works, you’re not just getting a piece of equipment—you’re gaining access to a suite of support services designed to aid in your project’s success. Our team offers comprehensive project management, engineering services, and equipment maintenance to keep your operations running smoothly. With over 50 locations nationwide, Maxim Crane Works is positioned to deliver unparalleled experience and support wherever your project is located.

Experience the benefits of working with a trusted leader in crane rental and lifting services. Contact Maxim Crane Works today to discuss your project needs and learn more about our carry deck crane rentals and support services.